Views: 0 Author: Site Editor Publish Time: 2025-05-06 Origin: Site

In modern infrastructure construction, selecting the right piping material is crucial to project success. High-Density Polyethylene (HDPE) pipes have become the ideal choice for numerous engineering projects due to their outstanding performance, being widely used in water supply, drainage, gas transmission, agricultural irrigation, and industrial fluid transportation. Below are ten core advantages that explain why HDPE pipes are increasingly being adopted in engineering projects.

1. Long Lifespan & Exceptional Durability

HDPE pipes can last over 50 years without corrosion, rust, or aging over time. Even under extreme climates and harsh geological conditions, they maintain excellent performance, making them a reliable long-term investment for infrastructure projects.

2. High Flexibility & Impact Resistance

HDPE pipes exhibit outstanding flexibility, adapting to unstable environments such as earthquakes, soil settlement, and temperature fluctuations, significantly reducing the risk of rupture due to ground movement. Their superior impact resistance also withstands external pressure and shocks, enhancing overall system safety.

3. Leak-Free Joint System

HDPE pipes utilize butt fusion or electrofusion welding technology to achieve monolithic, leak-free connections. This welding method greatly improves system sealing and safety, preventing liquid or gas leakage, making it ideal for applications with stringent sealing requirements like potable water and natural gas.

4. Excellent Corrosion & Chemical Resistance

Whether transporting acids, alkalis, or other industrial chemicals, HDPE pipes maintain long-term chemical stability without cracking or clogging due to corrosion. This characteristic is particularly suitable for wastewater treatment and chemical fluid transportation projects that demand high material resistance.

5. High Flow Efficiency

The smooth inner wall of HDPE pipes reduces friction, ensuring efficient flow and lowering pumping energy consumption. Unlike traditional metal pipes that suffer from rust and sediment buildup, HDPE maintains superior hydraulic performance over time, improving overall system efficiency.

6. Easy Installation & Cost Efficiency

HDPE pipes are lightweight, making them easier to transport, cut, and weld, significantly saving construction time and labor costs. Compared to traditional steel or concrete pipes, HDPE installation is more efficient, especially in complex terrains or space-constrained environments.

7. Eco-Friendly & Sustainable

HDPE material is recyclable, aligning with green environmental principles. Its long lifecycle and low maintenance needs help reduce resource waste and carbon emissions, making it an ideal choice for sustainable development.

8. Versatile Applications

HDPE pipes are widely applicable in various scenarios, including:

Municipal water supply & drainage

Agricultural irrigation systems

Gas & industrial chemical transportation

Power cable protection & communication conduits

Their excellent material properties ensure reliable solutions across multiple environments.

9. UV & Weather Resistance

HDPE pipes offer superior UV resistance, preventing degradation even with prolonged sun exposure, making them ideal for outdoor use. Their ability to withstand extreme temperatures ensures stable operation in both tropical and cold climates.

10. Low Maintenance Costs

Thanks to their corrosion resistance, anti-scaling properties, and excellent mechanical performance, HDPE pipes require almost no regular maintenance. This significantly reduces long-term operational costs and improves economic efficiency.

HDPE pipes combine durability, safety, installation convenience, and environmental benefits, making them a highly competitive piping solution for modern infrastructure projects. Whether in municipal construction, agricultural irrigation, or industrial transportation systems, HDPE is a trustworthy choice.

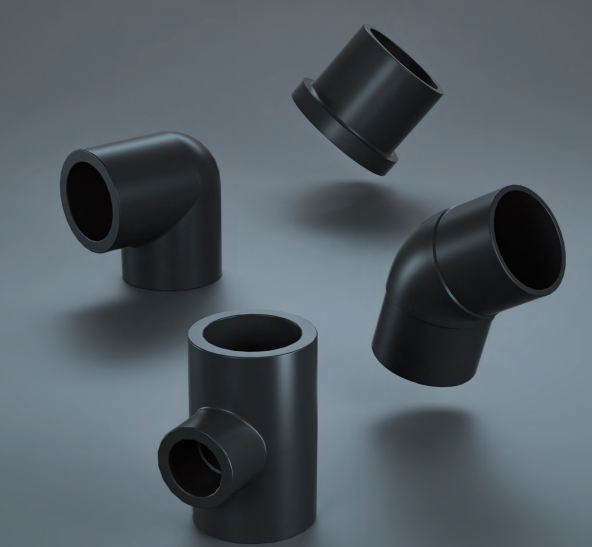

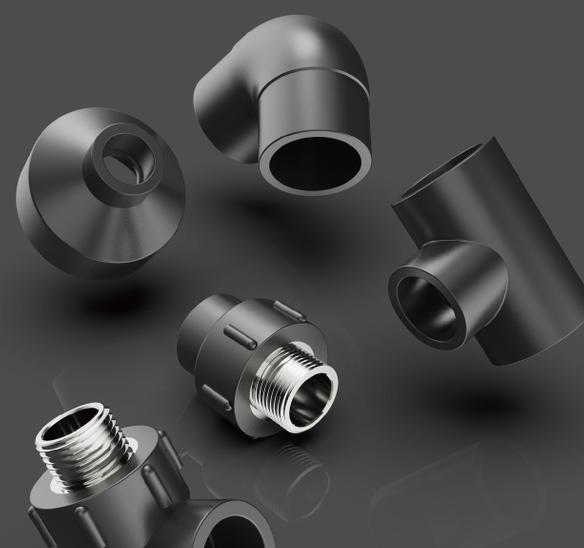

ERA's HDPE Pipe fittings

ERA's HDPE pipes are made from high-density polyethylene, a thermoplastic polymer composed of long ethylene or ethane chains. This composition ensures excellent insulation properties and exceptional durability. ERA's HDPE pipes are highly versatile, capable of withstanding significant stress due to their low creep rupture properties. Regardless of the application, these pipes deliver unmatched performance.

ERA's HDPE piping systems are widely used in micro and sprinkler irrigation, water supply networks, sewage and drainage pumping, telecom infrastructure, gas distribution, and various industrial projects. ERA's HDPE pipes provide robust protection against harmful UV rays while preventing contamination from toxic bacteria and chemicals.

ERA's HDPE Pipe Product Series

1. HDPE Electrofusion Pipes & Fittings

Uses electrofusion welding technology for high-strength, leak-free piping systems.

Suitable for gas transmission, water supply/drainage, and industrial fluid transportation.

Easy installation, ideal for confined or complex construction environments.

2. HDPE Butt Fusion Pipes & Fittings

Employs butt fusion technology, creating monolithic joints through heated pipe ends.

Ideal for large-diameter and medium/high-pressure fluid systems (e.g., municipal water supply, mining transportation).

Strong joints with high tensile resistance and system integrity.

3. HDPE Socket Fusion Pipes & Fittings

Features socket connections for simple, quick installation.

Designed for low-pressure, small-diameter networks (e.g., agricultural irrigation, park drainage).

Comprehensive fittings for above-ground and buried applications.

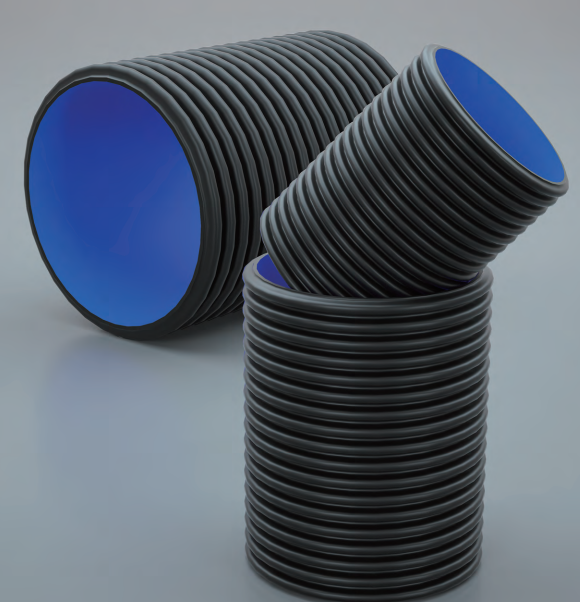

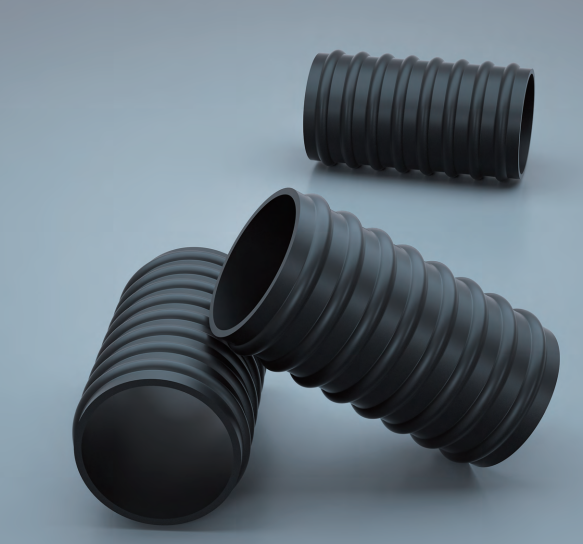

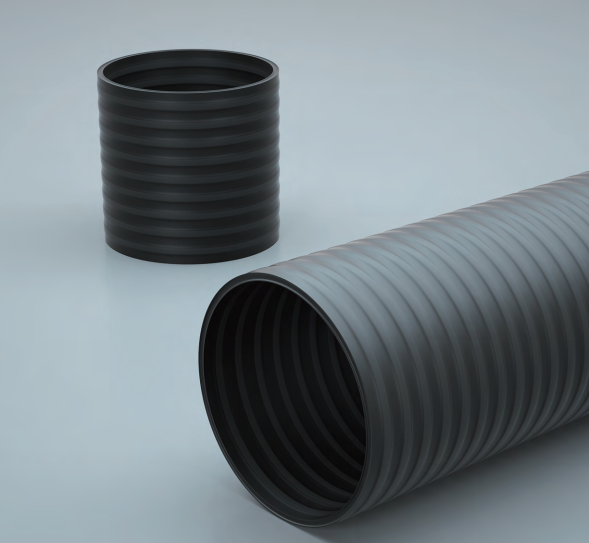

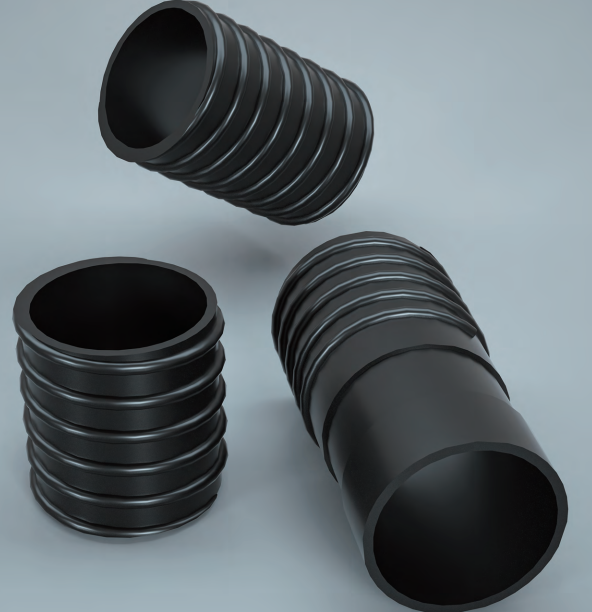

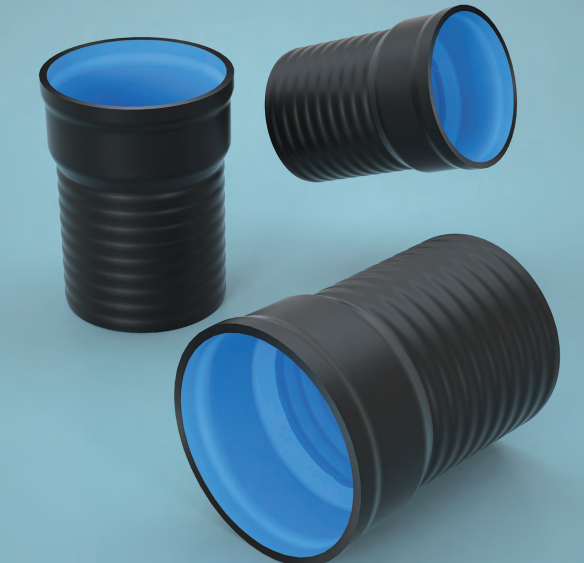

4. HDPE DWC Pipes (Double Wall Corrugated)

Dual-wall corrugated design combines lightweight construction with high ring stiffness.

Used in underground drainage, cable protection, and culvert projects.

High impact resistance for challenging geological conditions.

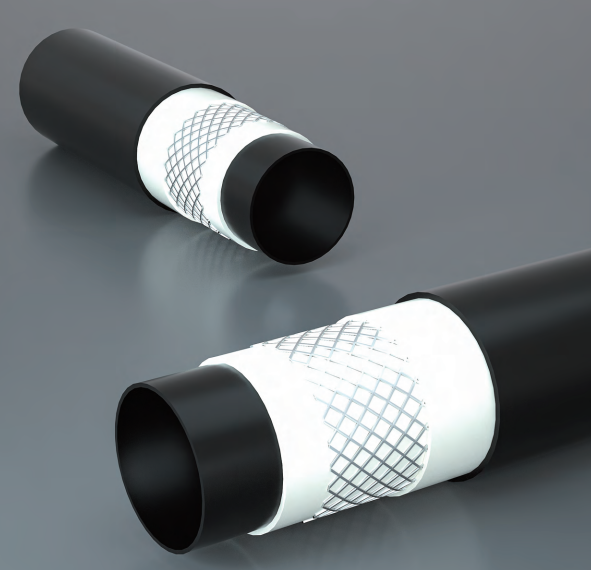

5. HDPE Steel Wire Reinforced Composite Pipes

Embedded steel wire mesh enhances strength and rigidity.

Designed for high-pressure fluid systems (municipal, industrial, mining).

Combines corrosion resistance with stability for complex environments.

6. HDPE Steel Strip Reinforced Spiral Corrugated Pipes

Steel strip skeleton with spiral corrugated exterior for ultra-high ring stiffness.

Widely used in urban drainage, stormwater networks, and wastewater treatment (large-diameter projects).

Lightweight yet strong, easy to install, cost-effective.

7. HDPE Hollow Wall Spiral Wound Pipes

Spiral Winding Technology for lightweight yet high-strength structure.

Suitable for non-pressure systems like sewage, water conservancy, and underground culverts.

Smooth interior minimizes flow resistance, improving transport/installation efficiency.

8. HDPE Structured Wall Wound Pipes (Krah Pipe)

Manufactured using German Krah technology with unique structured wall design.

High strength for large-scale municipal drainage, culverts, and tunnel drainage.

Rapid installation, strong adaptability, ideal for buried applications.

9. HDPE Triple-Wall Composite Reinforced Pipes

Three-layer design: wear-resistant inner layer, reinforced middle layer, protective outer layer.

For demanding industrial drainage and chemical wastewater transportation.

Balances strength with chemical resistance, reducing maintenance costs.

ERA's PE pipes and fittings are available in sizes ranging from 16mm to 2600mm, meeting diverse project requirements. For any engineering needs, feel free to consult us. We provide professional product recommendations to ensure the most suitable solutions for your projects.