Views: 0 Author: Site Editor Publish Time: 2025-11-10 Origin: Site

In the fields of building water supply and drainage and HVAC systems, the evolution of piping materials has always been driven by the pursuit of higher performance, longer service life, and greater safety margins. While traditional PP-R (random copolymer polypropylene) has become a market mainstream, a superior-performing material—PP-RCT (Polypropylene Random Crystallinity Temperature resistant)—is establishing itself as the new benchmark for high-standard engineering, grounded in solid materials science.

1. What is PP-RCT? A Micro-Level Revolution in Materials Science

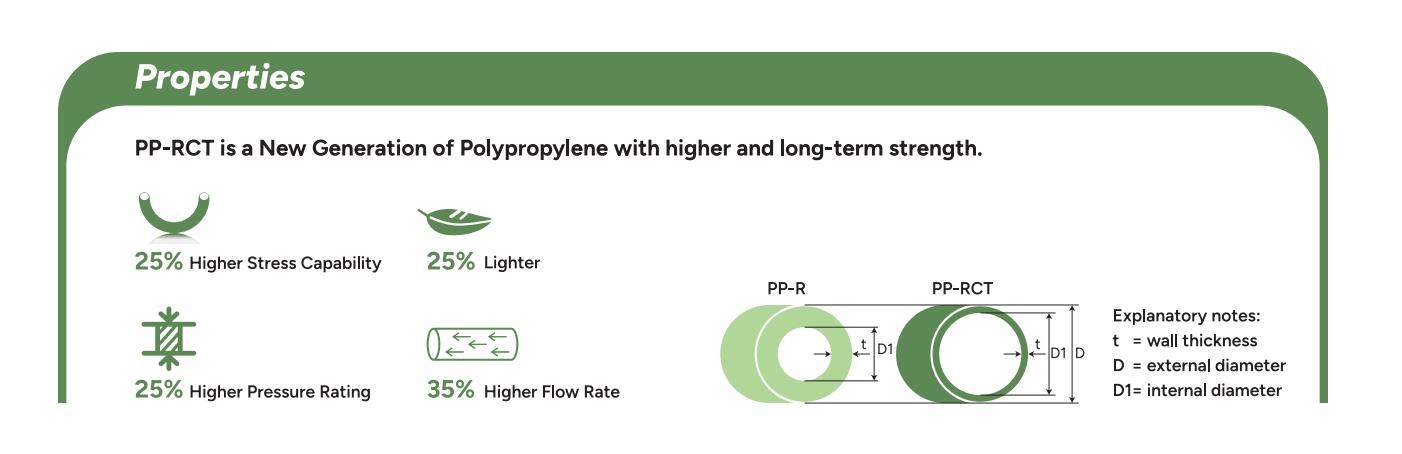

Simply put, PP-RCT is a "physically enhanced" version of PP-R. While their basic chemical compositions are similar, the fundamental difference lies in the crystalline structure of the polymer molecular chains.

Traditional PP-R: Has an irregular crystalline structure, which molecularly limits its long-term ability to withstand high temperatures and pressures.

PP-RCT: Utilizes advanced polymerization and modification processes to form a more complete and stable β-crystalline structure. This crystalline structure grants the molecular chains higher creep resistance and fatigue strength under stress.

Think of it like wood: traditional PP-R is like standard lumber, whereas PP-RCT is akin to laminated timber that has been directionally aligned and compressed, offering a qualitative leap in load-bearing and deformation resistance capabilities.

2. Core Performance Advantages: Data-Driven Excellence

The microstructural upgrade of PP-RCT directly translates into quantifiable, superior macro-level performance.

Higher Long-Term Hydrostatic Strength

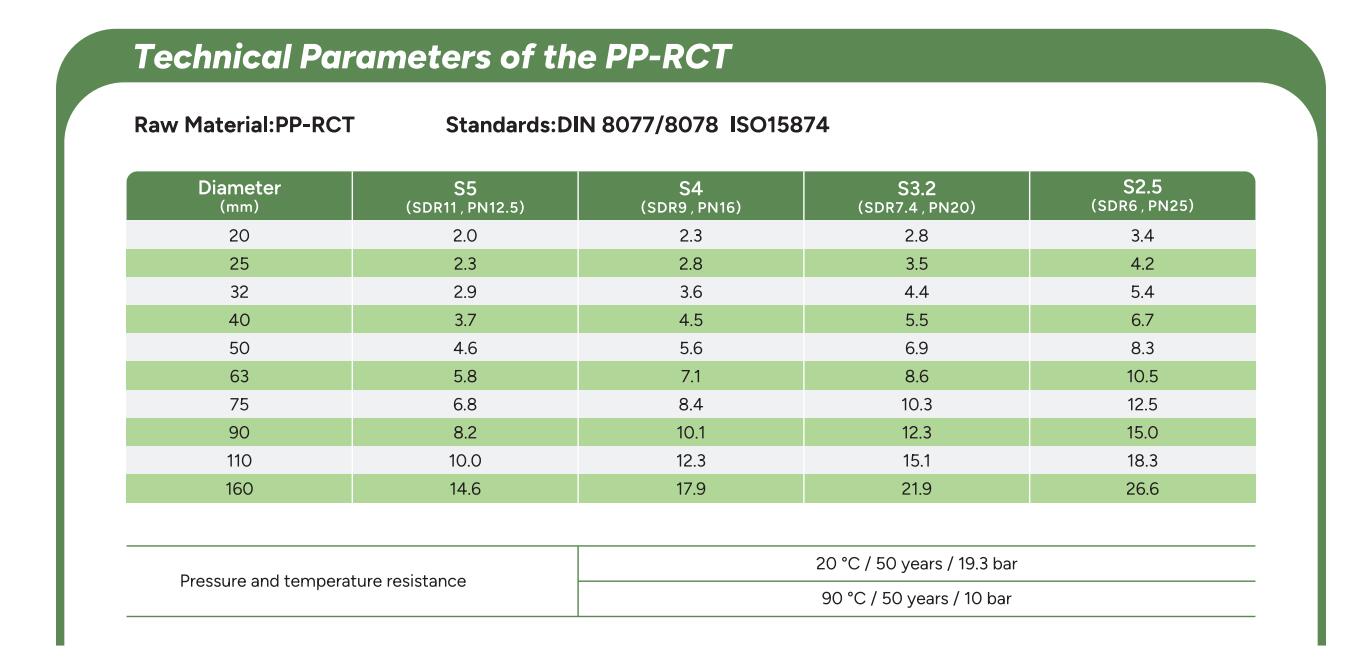

This is the core advantage of PP-RCT. According to the international standard ISO 15874, under the same service temperature (e.g., 70°C) and a 50-year design life premise, the Minimum Required Strength (MRS) for PP-RCT reaches PN 20/25 (related to pressure rating), demonstrating superior pressure-bearing capacity at high temperatures compared to standard PP-R. This means that at equal pressures, PP-RCT pipe walls can be thinner; and at equal wall thicknesses, it can withstand higher operating pressures, providing a greater safety margin.

Exceptional Creep Resistance and Temperature Performance

PP-RCT material shows significantly improved creep resistance (i.e., resistance to slow deformation under constant stress) at high temperatures. It is more suitable for high-temperature heating systems (e.g., 80°C or even higher transient temperatures) and high-temperature industrial water applications, effectively slowing down performance degradation due to long-term thermal aging and ensuring system integrity throughout the designed service life.

Excellent Impact Toughness

Even in low-temperature environments, PP-RCT maintains excellent impact resistance. This not only reduces the risk of pipe damage during transport and installation due to accidental impacts but also makes the system more reliable in applications in colder regions.

3. Standards and Certification: The Cornerstone of Performance Promise

PP-RCT is not a marketing concept but a material defined and regulated by stringent international standards.

Core International Standards:

ISO 15874: Plastics piping systems for hot and cold water installations — Polypropylene (PP) series standards, which explicitly define the classification and requirements for PP-RCT materials.

GB/T 28799 (Chinese National Standard): Similarly adopts the classification and performance requirements for PP-RCT, ensuring products in the domestic market comply with standards.

Compliance Certification: High-quality PP-RCT piping systems should also pass certifications such as Potable Water Safety Approvals, ensuring chemical inertness and hygienic safety when transporting domestic cold and hot water.

4. Why Choose Our PP-RCT System for Your Next Project?

As a Global Plastic Piping Solutions Provider, we offer not just an upgraded raw material, but a complete, engineering-validated system.

System Compatibility: We provide a full range of solutions from pipes to various fittings, ensuring consistent performance across the entire system after thermal fusion jointing, eliminating potential leakage risks.

Professional Engineering Support: We can provide full-process technical support for large or complex projects, from system design and installation guidance to pressure testing.

Quality Commitment: Premium PP-RCT raw materials sourced from renowned suppliers like Borealis, combined with fully automated production lines and stringent online quality control, form the foundation of our promise for a product service life spanning decades.

Conclusion: A Rational Investment for the Future

Choosing PP-RCT isn't just about selecting a pipe; it's about choosing a higher level of safety assurance and a longer service life for your building. For scenarios with stringent demands on system reliability, such as hospitals, hotels, high-end residences, and industrial applications, PP-RCT piping systems represent a forward-looking, rational investment.

It elevates the concept of "reliability" to new heights through robust materials science and international standards.