ERA Pipe Fitting Mould Factory, a branch of ERA Co., Ltd. (stock code: 002641), boasts over 30 years of experience in manufacturing plastic pipe fitting moulds, with an annual output of approximately 1,300 sets of high-performance moulds, such as PVC drainage fitting mould, PPR Hot&Cold fitting mould, CPVC pressure fitting mould, electric conduit fitting mould, PP irrigation fitting mould, PE butt-welding & electrofusion fitting mould, rain gutter fitting mould, valve mould, etc.

For ERA, the pipe fitting moulds it produces are essentially specialized tools used to shape various types of pipe fittings and are indispensable important equipment in modern manufacturing. From the common building water supply and drainage pipes in daily life to the complex mechanical pipeline systems in the industrial field, most of their core pipe fittings are manufactured through pipe fitting moulds.

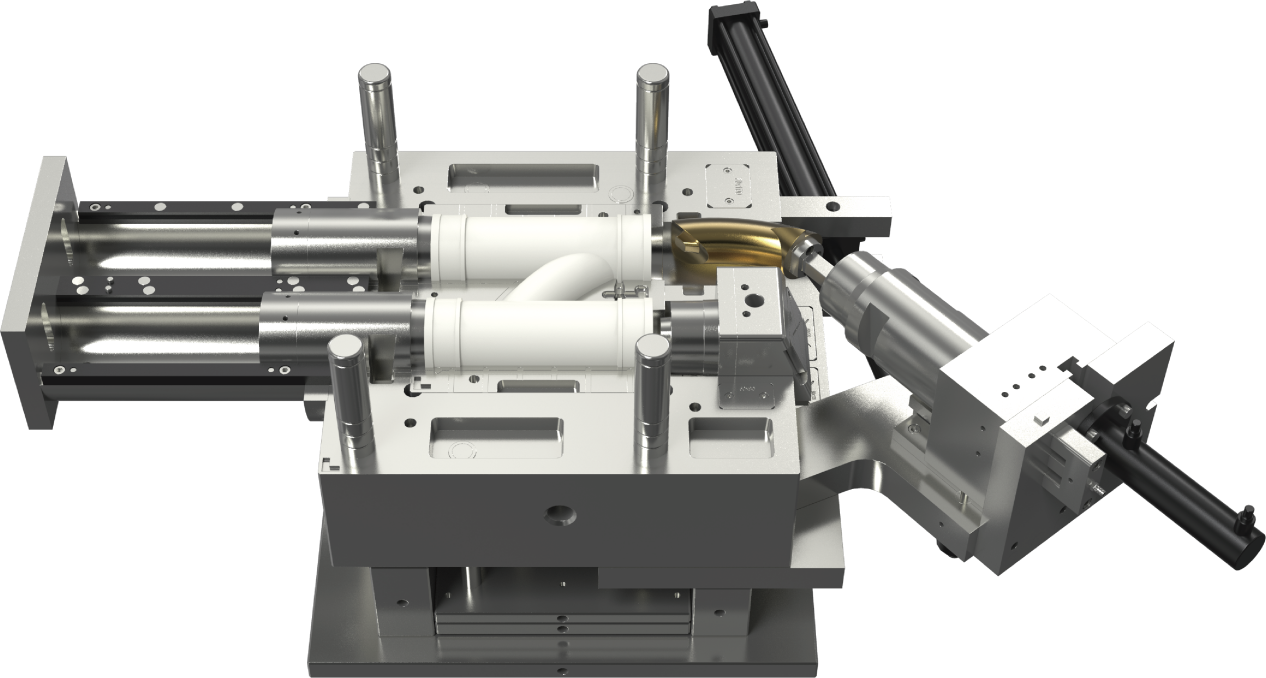

To achieve this industry value, the main function of pipe fitting moulds (including those produced by ERA) is to accurately shape plastic into pipe fittings of specific shapes and sizes (such as elbows, tees, couplings, reducers, flanges, etc.) through the injection molding proces.

In terms of the manufacturing process, the production of pipe fitting molds is a high-precision and high-complexity project. Firstly, engineers use professional design software (CAD/UG) to create 3D drawings and mould designs according to the usage requirements and performance standards of the pipe fittings.

Subsequently, suitable mold steel is selected, such as DIN 1.2316 with high hardness, strong wear resistance, and corrosion resistance. Then, CNC machining centers are used for processing with equipment including CNC milling machines, high-speed engraving machines, boring machines, high-speed lathes, and wire-cutting machines. QC will inspect all parts' dimensions to make sure they are within the tolerance range. Finally, the mould assembly workshop does the matching and assembles the moulds.

Pipe fitting molds have significant advantages. On the one hand, they can achieve mass production and standardized production of pipe fittings, ensuring consistent product dimensions and a feature that greatly improves production efficiency. On the other hand, with the help of the customizable design of the molds, they can meet the special requirements of different industries and working conditions for the shape, specifications, and performance of pipe fittings.

The application of pipe fitting moulds is becoming increasingly widespread, covering fields such as construction engineering, industrial pipe networks, fire protection, agricultural irrigation, electric power and communications, gas pipe networks, municipal pipe networks, etc.

If you want to develop a new pipe fitting mould project, ERA is your best choice. ERA is not only the professional mould manufacturer, but also have rich experience in pipe fitting production.